Industrial Growth Demands Engineered Mobility

Castor Wheel Manufacturers in Pune has evolved into one of India’s most strategically important industrial hubs. With strong clusters in automotive manufacturing, OEM assembly, fabrication, warehousing, logistics, electronics manufacturing, cold storage, pharmaceuticals, hospital infrastructure, and commercial facilities, the city operates on continuous internal movement of materials, components, and equipment—where Rexello Castors supports reliable and efficient industrial mobility solutions.

In these environments, mobility is not occasional—it is constant. Shop-floor carts, warehouse trolleys, assembly carriers, inspection tables, medical equipment and logistics systems move throughout the day, often under heavy and dynamic load conditions. The reliability of castor wheels used in these systems directly affects uptime, worker safety, throughput efficiency, floor integrity, and maintenance cost.

Although Pune has several castor wheel manufacturers and traders, industrial buyers increasingly move away from catalogue-grade wheels. Instead, they prefer engineered mobility solutions that perform predictably under real operating conditions. This is where Rexello Castors has become a preferred choice for Pune’s industrial and warehousing ecosystem.

When uptime, safety, and lifecycle value matter more than per-piece pricing, Rexello stands out as a castor wheel manufacturer built for industrial reality.

Why Pune’s Industrial Teams Actively Compare Castor Wheel Manufacturers

Industrial environments in Pune present a combination of stresses that standard wheels are rarely designed to handle. Warehouses operate for long duty hours with fast picking cycles and tight aisle turns. Automotive and fabrication units introduce vibration, impact loading, and uneven floors. OEM assembly lines demand precise directional control. Cold storage and pharma facilities add moisture, temperature control, and hygiene constraints.

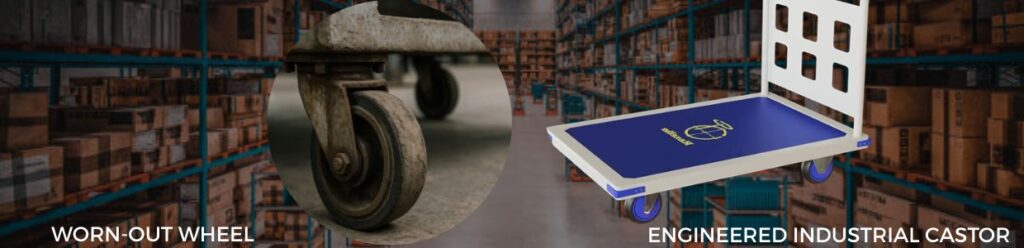

Most failures occur not because of extreme static load, but because of dynamic stress. Wheels face repeated acceleration and braking, sudden directional changes, torsional forces on brackets, vibration transfer from machinery, and floor transitions between concrete, epoxy, and ramps. Catalogue wheels often fail due to tread separation, bearing wobble, bracket deformation, flat spotting, corrosion, or loss of directional stability.

These failures lead to frequent trolley downtime, safety risks for operators, damage to flooring, and rising maintenance costs. As a result, Pune-based procurement and maintenance teams increasingly evaluate castor manufacturers based on engineering depth rather than catalogue variety.

Rexello addresses these challenges through engineered assemblies designed for real-world duty cycles, not ideal laboratory conditions.

Rexello – A Proven Castor Wheel Manufacturer for Pune’s Industrial Ecosystem

As one of the leading castor wheel manufacturers in Pune, Rexello manufactures a wide spectrum of castor wheel assemblies covering light-duty, medium-duty, heavy-duty, and special-purpose industrial applications. These solutions are widely used across Pune’s warehouses, fabrication shops, automotive plants, OEM assembly lines, pharma units, hospitals, cold storage facilities, and commercial infrastructure.

What differentiates Rexello from other castor wheel manufacturers in Pune is not just product range, but engineering integration. Each castor assembly is built around precision bearings, reinforced bracket geometry, optimized tread hardness, and shock-resistant bonding. Assemblies are selected and configured based on load behavior, floor condition, duty cycle, and environmental exposure—rather than relying solely on static load ratings.

For Pune industries, this results in smoother handling, lower vibration transfer, longer service life, and significantly reduced maintenance intervention compared to off-the-shelf wheels.

Engineering Matters More Than Static Load Ratings

One of the most common mistakes in castor selection is relying on static load ratings printed in catalogues. Static ratings do not account for shock loads, vibration, repeated turning, or acceleration forces that dominate real industrial use.

In Pune’s warehouses and factories, castors are subjected to dynamic load behavior—loads shift during movement, torsional forces act on brackets during turns, and vibration accelerates bearing fatigue. Rexello castors are engineered specifically for this reality, using deep or dual raceway bearings, torsion-resistant brackets, and controlled hardness wheels that protect both floors and equipment.

This engineering approach ensures predictable performance under continuous duty, making Rexello suitable for high-throughput environments such as automotive plants, logistics hubs, and fast-moving warehouses.

Castor Wheel Categories Manufactured by Rexello

Rexello’s product range is structured to meet varying industrial demands. Light-duty castors are commonly used in utility carts, hospitality support systems, retail stocking and housekeeping operations. Medium-duty castors support warehouse picking trolleys, OEM assembly carriers, and industrial push carts where balance between load and maneuverability is critical.

Heavy-duty castors are designed for platform trucks, fabrication tables, machine handling carts, and long-duty warehouse movement. For specialized environments, Rexello supplies castors for pharma clean-rooms, marine and coastal workshops, cold storage facilities, chemical exposure zones, and vibration-heavy industrial settings.

Each category is engineered with appropriate bearings, wheel materials, and bracket strength to ensure reliability across duty cycles.

Wheel Materials Used by Rexello for Pune Industries

Material selection is critical to performance. Rexello manufactures polyurethane (PU) wheels for silent rolling, floor protection, and durability in warehouses and logistics operations. Nylon wheels are preferred for chemical resistance, hygiene, and clean-room compatibility in pharma and electronics manufacturing.

For environments requiring shock absorption and grip on uneven floors, rubber wheels are used selectively. Cast iron wheels are employed in rugged fabrication and automotive applications where extreme load capacity is required. For corrosion-prone or hygiene-critical environments, stainless steel assemblies ensure rust-free performance and wash-down compatibility.

Each wheel assembly undergoes QC-tested bonding, hardness calibration, precision bearing integration, and batch traceability—ensuring consistent performance across repeat orders.

Why Pune Procurement Teams Prefer Rexello Over Catalogue Manufacturers

Procurement teams in Pune increasingly evaluate castors based on total cost of ownership, not just purchase price. Rexello castors reduce breakdown frequency, minimize bearing and tread failure, and extend replacement cycles. This translates into lower downtime, fewer maintenance calls, and safer shop-floor operations.

Rexello also supports OEM and industrial clients with CAD customization, bracket geometry optimization, floor-specific hardness selection, and dynamic load validation. Consistent batch quality and repeatable performance allow procurement teams to standardize mobility across facilities without variation risk.

Industries in Pune That Rely on Rexello Castors

Rexello castors are widely used in automotive manufacturing and engineering units, fabrication workshops, e-commerce and logistics warehouses, OEM assembly lines, electronics and clean-room environments, hospitals and pharma facilities, cold storage and food-grade systems, and commercial stocking and facility logistics.

Where mobility is continuous, heavy-duty, or reliability-critical, Rexello ensures safer handling, longer lifecycle, and better operational control.

Conclusion: Engineered Mobility Wins in Pune’s Industrial Landscape

Pune has no shortage of castor wheel suppliers, but industrial buyers require engineered mobility, not low-cost catalogue compromises. Rexello delivers dynamic load performance, reinforced brackets, precision bearings, corrosion-resistant assemblies, and OEM-grade customization.

For warehouses, automotive plants, fabrication shops, pharma units, cold storage facilities and commercial mobility systems in Pune, Rexello is the castor wheel manufacturer trusted for uptime, safety, and lifecycle value.

CTA – Rexello

Need engineered castor wheels for Pune-based industrial or OEM applications?

Get CAD support, dynamic load validation, and application-specific mobility solutions from Rexello.

📧 info@rexello.com | 📞+91-79001 47477 | 🌐 www.rexello.com

.webp)