Caster Wheel Manufacturer in Malaysia – Industrial Engineering for Material Movement

Caster Wheel Manufacturer in Malaysia – Industrial Mobility for Warehousing & Manufacturing

Malaysia has a thriving industrial and logistics ecosystem — from automotive and fabrication units to FMCG warehouses, airport baggage systems, commercial trolleys, retail distribution, and clean- room movement equipment. For continuous productionand safe material handling, selecting the right caster wheel manufacturer in Malaysia becomes a critical procurement decision for factories,warehouses, and OEM integrators.

Industrial mobility is not just about movement — it is about:

- reducing downtime

- improving load efficiency

- minimizing repair cost

- ensuring smooth shop-floor operations

- and extending trolley lifecycle

Many Malaysian procurement teams evaluate leading caster wheel suppliers for:

- standard trolleys

- heavy-duty platform trucks

- machine mobility

- rack and shelf movement

- clean-room carts

- pallet & fabrication tables

Chinese and Malaysian production facilities offerstandardized caster wheels, typically cost-effective for general-duty movement. However, when duty cycle, uptime reliability, and floor conditions matter, OEMs and factories prefer engineered caster wheels with long lifecycle performance — like Rexello.

Where Malaysian Facilities Use Industrial Caster Wheels

Industrial casters are widely deployed across:

- warehouse order-picking trolleys

- automotive assembly line movement

- airport luggage & terminal mobility

- chemical and food-grade carts

- fabrication bays and metal shops

- retail & cold storage racks

- distribution centers & logistics carriers

- textile movement & packaging rooms

Maintenance teams rely on high-performance wheels to:

- reduce vibration>

- ensure stable directional movement

- support repetitive material flow

- and prevent floor damage

Why Malaysian Procurement Teams Evaluate Rexello

Malaysia has an efficient market for standard caster wheels. However,heavy-duty industries and 24×7 operations prefer engineered assemblies from Rexello due to:

✔ Predictable Load Performance

Rexello caster wheels handle:

- 250–500 kg (light duty)

- 500–1,200 kg (heavy duty)

- and reinforced dual-wheel assemblies beyond 1.2 tons

Engineered dynamic load performance matters more than just static load numbers.

✔ Floor Compatibility

Shop-floor conditions vary across Malaysian facilities — RCC, epoxy, tiles, steel plate, chemical room, or cold storage. Rexello ensures:

- minimal floor abrasion

- silent mobility

- long lifecycle

- better directional control

✔ Lower Maintenance Cost

Factories lose far more in downtime and breakdown costs than in procurement cost per wheel. Rexello wheels:

- reduce failures

- extend trolley lifespan

- minimize replacement cycles

- lower maintenance budget

This is a major advantage over low-cost imports.

Material Choices for Malaysian Industry Conditions

Rexello manufactures industrial caster wheels using:

- Polyurethane (PU): silent, high lifespan, warehouse mobility

- Nylon: high load + chemical resistance

- Rubber: vibration and impact control

- Cast Iron: rugged for fabrication, furnace & heavy shop floors

- Stainless Steel: corrosion-free for marine, pharma & clean-room conditions

Each wheel undergoes:

- precision bonding

- CNC bracket fabrication

- load test rating

- corrosion protection

- bearing optimization

This level of engineering support is valuable for OEM builders, plant managers, and mobility equipment suppliers in Malaysia.

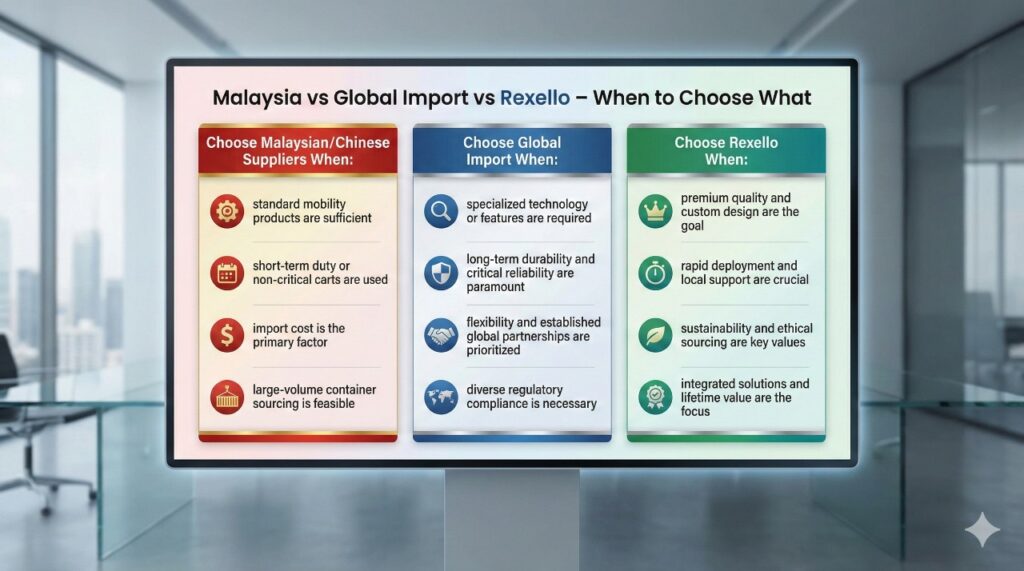

Malaysia vs Global Import vs Rexello – When to Choose What

Choose Malaysian/Chinese Suppliers When:

- standard mobility products are sufficient

- short-term duty or non-critical carts are used

- import cost is the primary factor<

- large-volume container sourcing is feasible

Choose Rexello When:

- mobility is continuous duty

- downtime costs more than wheel procurement

- heavy fabrication or repetitive turning cycles exist

- floor conditions require material selection expertise

- stainless steel, dual wheels, or precision bearing assemblies are required/li>

- CAD-based engineering is required before mass purchase

Why OEMs in Malaysia Prefer Rexello for Engineering Value

Rexello provides:

- CAD support for custom brackets

- bearing recommendation

- custom hardness selection

- load test validation

- bulk packaging for exports

- galvanized or stainless housings

- shop-floor mobility engineering

This reduces procurement risk, improves safety, and increases lifecycle ROI — making Rexello a more strategic sourcing partner.

Malaysia + Global Export Confidence

Rexello supplies engineered caster wheels globally, including:

- Middle East

- Africa

- South Asia

- European OEM units

Export batches are:

- pallet packed

- moisture controlled

- load-certified

- traceable with batch QC

- optimized for industrial deployment

Conclusion

Malaysia has several caster wheel manufacturers that suit standard-duty equipment. However, for continuous-duty warehouses, fabrication plants, logistics hubs, OEM machinery, and 24×7 mobility systems, Rexello caster wheels deliver better value through:

- engineered lifecycle performance

- lower maintenance frequency

- predictable uptime

- floor-optimized materials

- CAD and engineering support

If mobility impacts uptime, Rexello is the more reliable partner than low-cost imports.

CALL TO ACTION (Rexello)

Need engineered caster wheels or customized trolley assemblies for Malaysian or global operations? Request CAD drawings, load sheets, or OEM solutions today.

+91-79001 47477

info@rexello.com

FAQ’s :-

Q1: When should factories choose Malaysian caster wheel suppliers?

Factories should choose Malaysian suppliers when they need standard-duty caster wheels at lower cost, and the application is non-critical, short-term, or mainly price-driven.

Q2: Can Rexello supply stainless steel and corrosion-resistant caster assemblies?

Yes — Rexello supplies stainless steel and corrosion-resistant caster assemblies designed for marine, pharma, and clean-room environments.

Q3: How does engineered load performance improve uptime?

Engineered load performance prevents wheel failures, supports heavier duty cycles, and reduces downtime—resulting in more reliable uptime on the shop floor.

Q4: What materials are ideal for warehouse mobility in Malaysia?

Polyurethane (PU) wheels are ideal because they provide silent movement, long lifespan, and smooth warehouse mobility in Malaysian conditions.

.webp)