Castors and Wheels Suppliers in India – Industrial Mobility and Heavy-Duty Movement Solutions

India’s industrial landscape is rapidly evolving with major infrastructure expansions in e-commerce warehousing, automotive plants, fabrication workshops, cold storage, pharmaceutical facilities, marine operations, OEM machinery manufacturing, and aviation logistics. Every one of these sectors relies on castors and wheels for safe and continuous movement of material, equipment, pallets, loads, and assembly-line carts.

Choosing reliable castors and wheels suppliers in India is no longer a basic procurement decision — it directly affects production uptime, worker efficiency, floor safety, and annual maintenance budgets.

Factories that run for 16–24 hours a day, especially in logistics-heavy industries, cannot afford regular wheel failure, bracket bending, or bearing fatigue. Engineered mobility systems are essential for predictable performance, reduced breakdowns, and long lifecycle ROI.

Where Indian Facilities Use Castors and Wheels

- warehouse picking and material transfer trolleys

- OEM assembly line carts

- fabrication tables and welding bays

- cold storage and food distribution

- retail distribution and inventory systems

- pharmaceutical clean-room carts

- airport terminal carts and aviation movement systems

- marine workshops and heavy engine mobility

Indian shop floors have diverse conditions — from epoxy-coated warehouse floors to harsh fabrication environments — making material selection and engineering validation critical.

Why Procurement Teams Compare Multiple Castors and Wheels Suppliers in India

India has numerous castor suppliers offering:

- light-duty wheels

- medium-duty assembly solutions

- standard warehouse trolleys

- commodity-grade castors

These suppliers work well when:

- usage is short-term

- load cycles are routine

- movement is occasional

- floor wear is minimal

However, continuous-duty or heavy-duty industrial applications need more than just catalogue wheels. Maintenance teams prefer engineered solutions from Rexello because:

Predictable Load and Duty Performance

Static load numbers alone do not define performance. Industrial carts move through:

- tight turns

- slopes and uneven floor patches

- vibration and machine movement

- impact zones during loading/unloading

Rexello wheels are engineered and validated for these environments.

Lower Lifecycle Cost

Upfront wheel cost is low, but maintenance downtime is expensive.

Rexello wheels:

- minimize breakdown

- extend trolley lifespan

- reduce repair frequency

- control floor abrasion

- improve movement efficiency

This reduces annual maintenance and operational cost significantly.

Engineering Backing

Rexello provides:

- CAD-based bracket design

- wheel hardness optimization

- bearing selection guidance

- corrosion treatment options

- stainless steel assemblies for pharma/marine

- custom mountings for OEM systems

This is far beyond typical commodity sourcing.

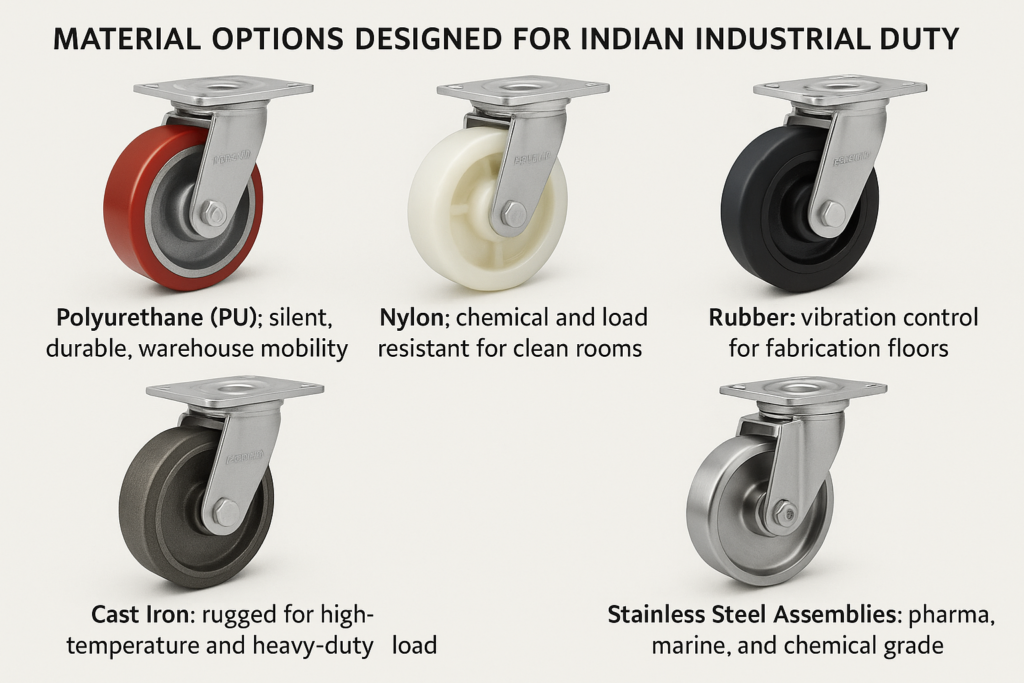

Material Options Designed for Indian Industrial Duty

Rexello manufactures wheels using:

- Polyurethane (PU): silent, durable, warehouse mobility

- Nylon: chemical and load resistant for clean rooms

- Rubber: vibration control for fabrication floors

- Cast Iron: rugged for high-temperature and heavy-duty load

- Stainless Steel Assemblies: pharma, marine, and chemical grade

Each wheel undergoes:

- precision molding

- bonding validation

- corrosion treatment

- CNC bracket fabrication

- dynamic load testing

- ball raceway / bearing optimization

- export-grade finishing

Rexello vs Standard Indian Castor Suppliers – Choosing the Right Partner

Standard Suppliers are Suitable When:- duty cycle is low

- cost is the only parameter

- carts have light or occasional usage

- uptime affects productivity

- heavy-duty or continuous operations are common

- floor compatibility matters

- turning cycles cause bearing fatigue

- stainless steel or corrosion resistance is needed

- OEM mobility needs CAD customization

- precision bearings ensure directional stability

Export + Industrial Deployment Confidence

Rexello castors and wheels are supplied across India and exported globally. Batches are:

- pallet packed

- moisture protected

- load-certified

- batch traceable

- optimized for industrial deployment

Facilities across Middle East, Singapore, Africa, Europe, and South Asia rely on Rexello for OEM and heavy-duty mobility systems.

Conclusion

India has a strong base of castors and wheels suppliers, but when uptime, lifecycle value, floor compatibility, and engineering predictability matter, Rexello delivers superior performance.

Procurement teams benefit from:

- lower maintenance cycles

- long-duty operational performance

- CAD and engineering support

- reduced total lifecycle cost

- floor-safe mobility

- stainless steel and heavy-duty designs

For industrial, OEM, warehouse, fabrication, marine or clean-room mobility systems, Rexello is the strategic sourcing partner that ensures performance, reliability, and lifecycle ROI.

REXELLO CTANeed engineered castors and wheels for industrial or OEM applications in India?

Request CAD drawings, load sheets or custom trolley assemblies.

+91-79001 47477

info@rexello.com

FAQ’s:-

Q1: How do engineered castors improve mobility in Indian warehouses and factories?

Engineered castors make heavy equipment easy to move, reduce manual lifting, speed up material handling, and allow quick layout changes inside warehouses and factories. They also protect floors, improve safety with better control/braking, and increase productivity by reducing worker effort and time spent shifting loads.

Q2: When should procurement teams choose heavy-duty castors instead of standard wheels?

Procurement teams should choose heavy-duty castors when loads are very heavy, equipment moves frequently, floors are rough, or safety and durability are critical. They’re ideal for factories, warehouses, logistics and industrial machinery where standard wheels may wear out or fail.

Q3: Can Rexello design stainless steel or corrosion-resistant assemblies for pharma/marine use?

Yes—Rexello can engineer stainless steel and corrosion-resistant castor assemblies specifically suited for pharma, food-grade, marine and harsh chemical environments.

Q4: How does proper bearing selection reduce maintenance cost and improve uptime?

Proper bearing selection reduces friction and wear, so wheels roll smoother, last longer, and need fewer replacements—resulting in lower maintenance cost and higher uptime for equipment.

.webp)